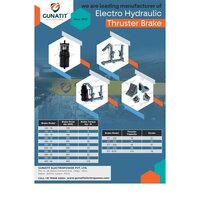

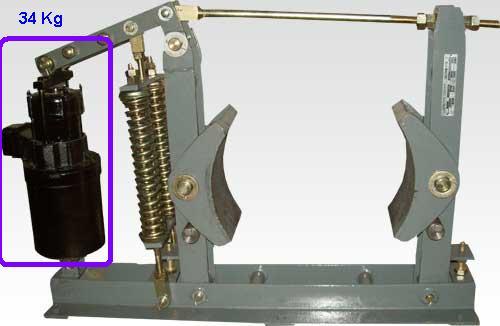

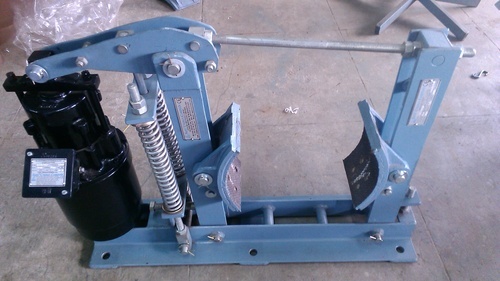

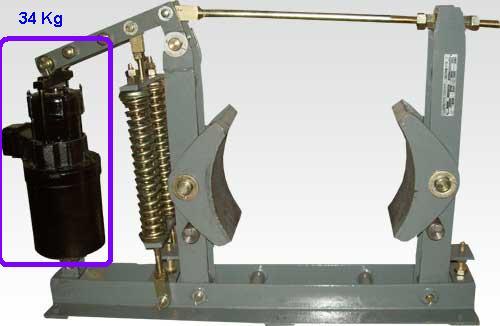

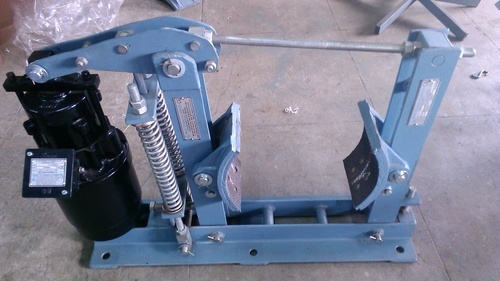

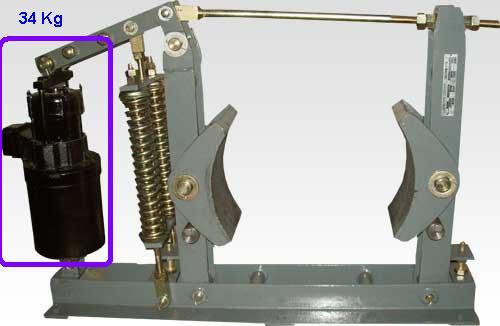

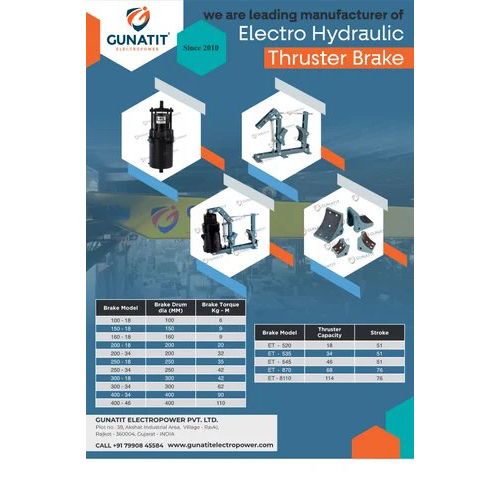

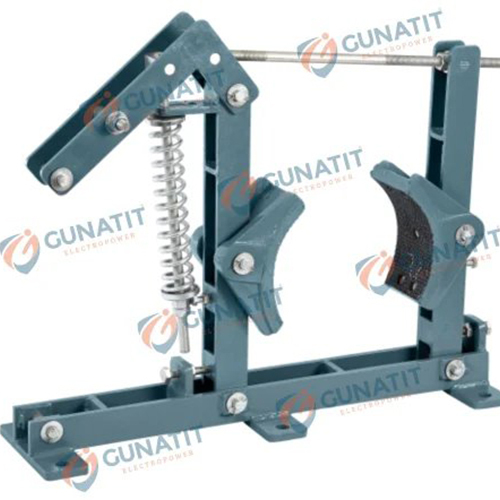

Thruster Brake

6000.00 आईएनआर/Unit

उत्पाद विवरण:

- रंग नीला

- उपयोग औद्योगिक

- साइज विभिन्न आकार उपलब्ध हैं

- शर्त नया

- ऑपरेटिंग मोड Automatic

- बिजली की आपूर्ति Electric

- वोल्टेज वोल्ट (v)

- Click to view more

X

थ्रस्टर ब्रेक मूल्य और मात्रा

- यूनिट/यूनिट्स

- 1

- यूनिट/यूनिट्स,

थ्रस्टर ब्रेक उत्पाद की विशेषताएं

- विभिन्न आकार उपलब्ध हैं

- वोल्ट (v)

- नीला

- Electric

- Automatic

- औद्योगिक

- नया

थ्रस्टर ब्रेक व्यापार सूचना

- 10000 प्रति वर्ष

- 1 दिन

उत्पाद विवरण

A thruster brake, also known as an electromagnetic thruster brake, is a type of braking system used to control the speed and stop the motion of heavy machinery and equipment. It is commonly employed in various industrial applications, such as cranes, hoists, and winches. The primary function of a thruster brake is to provide precise and reliable braking control in situations where the equipment needs to stop quickly and safely.

Here's how a thruster brake works:

1. Electromagnetic Mechanism: The core component of a thruster brake is an electromagnetic coil. When an electrical current is applied to the coil, it generates a magnetic field. This magnetic field attracts an armature, which is connected to the braking mechanism.

2. Braking Force: When the magnetic field is activated, the armature is pulled towards the coil, causing a set of friction pads or brake shoes to make contact with a rotating drum or disc attached to the machinery's moving part. This contact generates friction, which results in a braking force that slows down and eventually stops the motion of the equipment.

3. Control System: Thruster brakes are typically controlled by a dedicated control panel that manages the application and release of the electromagnetic force. Operators can control the brake's operation manually or automatically, depending on the application's requirements.

4. Quick Response: Thruster brakes are known for their rapid response time, making them suitable for applications where precise and immediate stopping is essential for safety and productivity.

5. Maintenance: Regular maintenance is required to ensure the continued effectiveness of the thruster brake. This includes monitoring the wear of the friction materials and ensuring the electromagnetic components are functioning correctly.

Applications of Thruster Brake:

1. Cranes: Thruster brakes are frequently used in overhead cranes, gantry cranes, and mobile cranes to control the movement and positioning of loads. They ensure that the crane can stop quickly and precisely to prevent accidents and ensure efficient material handling.

2. Hoists: Thruster brakes are utilized in hoisting equipment, such as electric wire rope hoists and chain hoists, to control the ascent and descent of loads. They provide reliable and adjustable braking force to maintain load control and safety.

3. Winches: Winches are used in various applications, such as marine, offshore, and construction. Thruster brakes are used to control the winding and unwinding of cables or ropes, ensuring that loads are lifted and lowered safely.

4. Conveyors: Thruster brakes are employed in conveyor systems to control the speed and stop the movement of materials on the conveyor belts. They are essential for maintaining material flow and preventing conveyor jams.

5. Machine Tools: Thruster brakes can be found in machine tools like lathes, milling machines, and grinding machines to quickly stop the rotation of cutting tools and workpieces, ensuring precision in machining operations.

6. Mining Equipment: In the mining industry, thruster brakes are used in equipment like winches, conveyors, and draglines to control the movement of heavy loads and machinery in potentially hazardous environments.

7. Material Handling Equipment: Thruster brakes are used in various material handling equipment, including forklifts and stacker-reclaimers, to provide precise control and safe operation when moving and stacking materials.

8. Elevators and Lifts: Thruster brakes can be found in freight elevators and lifts to ensure smooth and controlled stops between floors, preventing sudden jerks and ensuring passenger safety.

9. Stage and Theater Equipment: In the entertainment industry, thruster brakes are used in equipment like motorized curtains and stage lifts to control the movement and positioning of stage elements.

10. Foundries and Steel Mills: Thruster brakes are used in heavy machinery and equipment in foundries and steel mills, such as ladle cranes and rolling mills, to control the movement of molten metal and heavy steel products.

11. Paper and Pulp Industry: Thruster brakes are utilized in paper and pulp processing machinery to control the winding and unwinding of paper rolls and maintain precise tension control.

Frequently Asked Questions:

Q. What is a thruster brake?

Ans: A thruster brake, also known as an electromagnetic thruster brake, is a braking system used in industrial applications to control and stop the motion of heavy machinery and equipment. It relies on electromagnetic force to create friction and slow down or halt the motion of a rotating part.

Q. How does a thruster brake work?

Ans: Thruster brakes use an electromagnetic coil to generate a magnetic field, which attracts an armature connected to a set of friction pads or brake shoes. When the armature is pulled in, it makes contact with a rotating drum or disc, creating friction and providing braking force to stop the machinery.

Q. What are the advantages of thruster brakes

Ans: Thruster brakes offer quick and precise stopping of heavy machinery, making them suitable for safety-critical applications. They are adjustable and capable of handling heavy loads, providing reliable braking control.

Q. Where are thruster brakes commonly used?

Ans: Thruster brakes find applications in a variety of industries, including cranes, hoists, winches, conveyors, machine tools, mining equipment, elevators, stage equipment, and more, wherever heavy machinery and equipment require controlled stopping.

Q. What types of maintenance do thruster brakes require?

Ans: Regular maintenance includes monitoring the wear of the friction materials (brake shoes or pads) and ensuring that the electromagnetic components are functioning correctly. Lubrication, cleaning, and periodic inspections are typically part of the maintenance routine.

Q. Are thruster brakes suitable for outdoor or harsh environments?

Ans: Thruster brakes can be designed for outdoor or harsh environments with features like weatherproof enclosures, special coatings, and seals to protect against dust and moisture, making them suitable for use in various conditions.

Q. Can thruster brakes be controlled remotely?

Ans: Yes, thruster brakes can be integrated into control systems and can be operated remotely, allowing for automation and remote monitoring of equipment.

Q. Are thruster brakes energy-efficient?

Ans: Thruster brakes consume electricity only when they are engaged, which makes them energy-efficient. They do not produce heat during normal operation, reducing energy waste.

Q. What is the lifespan of thruster brakes?

Ans: The lifespan of a thruster brake depends on factors like usage, maintenance, and the specific application. With proper maintenance, they can have a relatively long service life.

Q. Are there safety considerations when using thruster brakes?

Ans: Yes, safety is a primary concern when using thruster brakes, especially in applications involving heavy loads and machinery. Regular maintenance and

following safety guidelines are essential to ensure safe operation.

Q. Can thruster brakes be retrofitted to existing equipment?

Ans: In many cases, thruster brakes can be retrofitted to existing machinery to improve control and safety. However, it's essential to consult with a qualified engineer or technician to determine compatibility and feasibility.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

08045801632

08045801632

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें मुझे निःशुल्क कॉल करें

मुझे निःशुल्क कॉल करें