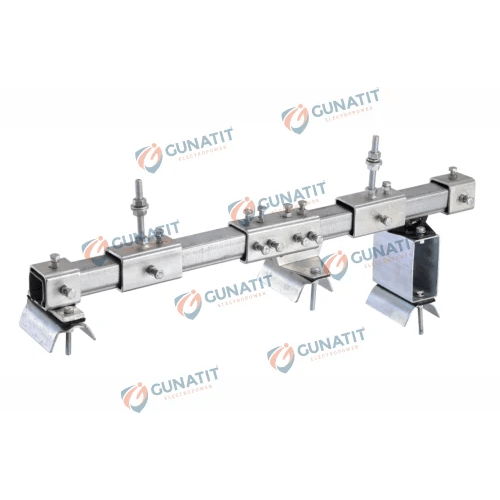

C Rail Festoon System for Crane

350 आईएनआर/Meter

उत्पाद विवरण:

- साइज 30 x 32 x 1.5 मिमी

- उपयोग Industrial

- लम्बाई 4.5 एमटीआर मानक लंबाई मीटर (m)

- शर्त

- ऑपरेटिंग मोड Automatic

- Click to view more

X

क्रेन के लिए सी रेल फेस्टून सिस्टम मूल्य और मात्रा

- मीटर/मीटर

- मीटर

- 50

क्रेन के लिए सी रेल फेस्टून सिस्टम उत्पाद की विशेषताएं

- Automatic

- 30 x 32 x 1.5 मिमी

- 4.5 एमटीआर मानक लंबाई मीटर (m)

- Industrial

क्रेन के लिए सी रेल फेस्टून सिस्टम व्यापार सूचना

- मुंद्रा, भारत

- कैश ऑन डिलीवरी (COD), चेक

- 500 प्रति सप्ताह

- दिन

- Yes

- नमूना लागत, शिपिंग और करों का भुगतान खरीदार द्वारा किया जाना है

- लकड़ी के बक्से में पैकिंग

- ऑल इंडिया

- एक आईएसओ 9001: 2008 प्रमाणित कंपनी

उत्पाद विवरण

A festoon system is a crucial component in overhead cranes and material handling systems, providing power and control to mobile equipment such as cranes and hoists. The festoon system consists of a trolley, cable or hose carriers, and cables or hoses. The C Rail Festoon System is a specific type of festoon system that utilizes a C-shaped track for guiding and supporting the cables.

Here are some key features and components of a C Rail Festoon System for a crane:

1. C Rail:

The C-shaped rail serves as the primary track for the festoon system. It is typically mounted along the runway of the crane.

The rail provides a guided path for the trolley, which carries the festoon cables.

2. Trolley:

The trolley is mounted on the C Rail and travels along its length.

It carries the festoon cable carriers, ensuring they move smoothly along the designated path.

3. Festoon Cable Carriers:

Festoon cable carriers are flexible containers that hold and protect the power and control cables.

They are attached to the trolley and move with it along the C Rail.

4. Cables and Hoses:

The festoon system accommodates various types of cables and hoses, including power cables, control cables, and air hoses.

These cables provide electrical power and control signals to the crane's motors and control systems.

5. End Stops:

End stops are installed at the ends of the C Rail to prevent the trolley from accidentally sliding off.

They ensure the festoon system stays within the designated path.

6. Collector:

In some festoon systems, a collector assembly is used to transfer power from the stationary power source to the moving trolley.

The collector slides along a conductive surface on the C Rail, maintaining electrical contact.

7. Supporting Structure:

The festoon system is typically supported by a structure that is securely attached to the crane or the building structure.

8. Weatherproofing:

Festoon systems are often designed to be weatherproof to protect cables and components from environmental factors such as rain, snow, and dust.

The C Rail Festoon System is known for its reliability and ease of installation. It provides a cost-effective solution for managing cables in crane applications where mobility is essential. Proper maintenance and periodic inspections are important to ensure the system's optimal performance and to prevent issues such as cable wear or misalignment.

C Rail Festoon System Specifications:

1. Thickness: 2 mm

2. Model Name/Number: CRFS3032

3. Weight: Upto 1 Kg

4. Surface Treatment: Galvanized

5. Size/Capacity: 30 x 32 , 40 x 40

6. Material: Stainless Steel

Frequently Asked Questions (FAQ):

Q. What is a C Rail Festoon System?

Ans: A C Rail Festoon System is a type of cable management system used in overhead cranes. It consists of a C-shaped rail mounted along the crane runway, a trolley that travels along the rail, and festoon cable carriers that hold power and control cables.

Q. What is the purpose of a C Rail Festoon System in a crane?

Ans: The primary purpose is to provide a guided path for power and control cables, ensuring they move with the crane's trolley. It allows for the safe and efficient transmission of electrical power and control signals to the moving parts of the crane.

Q. What types of cables are typically used in a C Rail Festoon System?

Ans: C Rail Festoon Systems accommodate various cables, including power cables, control cables, and sometimes air hoses. These cables supply electricity and control signals to the crane's motors and other components.

Q. How is the festoon system powered?

Ans: The festoon system is typically powered through a collector assembly. The collector maintains electrical contact with a conductive surface on the C Rail, transferring power from a stationary source to the moving trolley.

Q. What are the advantages of using a C Rail Festoon System in crane applications?

Ans: Some advantages include ease of installation, cost-effectiveness, and reliability. The system allows for the efficient management of cables in dynamic crane environments.

Q. How is the C Rail Festoon System weatherproofed?

Ans: Festoon systems are often designed to be weatherproof to protect cables and components from environmental elements. This may involve using durable materials, seals, and other protective measures to prevent damage from rain, snow, or dust.

Q. What maintenance is required for a C Rail Festoon System?

Ans: Regular inspections and maintenance are essential to ensure optimal performance. This may include checking for cable wear, proper alignment, and the condition of moving parts. Lubrication and cleaning may also be part of the maintenance routine.

Q. Can a C Rail Festoon System be retrofitted onto existing cranes?

Ans: Yes, in many cases, C Rail Festoon Systems are designed to be easily retrofitted onto existing crane systems. However, it's important to consult with the system manufacturer or a qualified engineer to ensure compatibility and proper installation.

Q. Are there weight and speed limitations for C Rail Festoon Systems?

Ans: Yes, there are typically weight and speed limitations that manufacturers specify for C Rail Festoon Systems. Exceeding these limits can lead to premature wear and potential system failures.

Q. Can a C Rail Festoon System be customized for specific crane applications?

Ans: Yes, many manufacturers offer customizable options to meet the specific requirements of different crane applications. This may include variations in cable types, lengths, and additional features based on the crane's design and operating conditions.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

08045801632

08045801632

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें