Cable Carrier

50 INR/Number

Product Details:

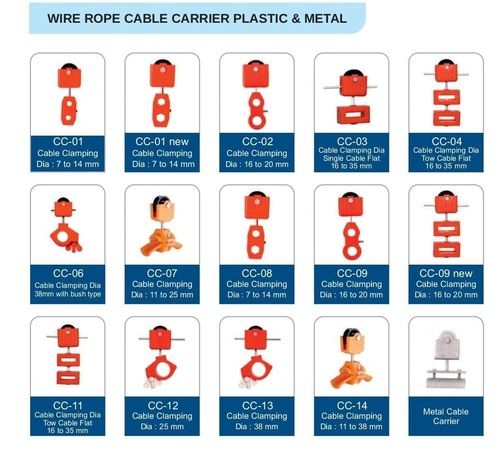

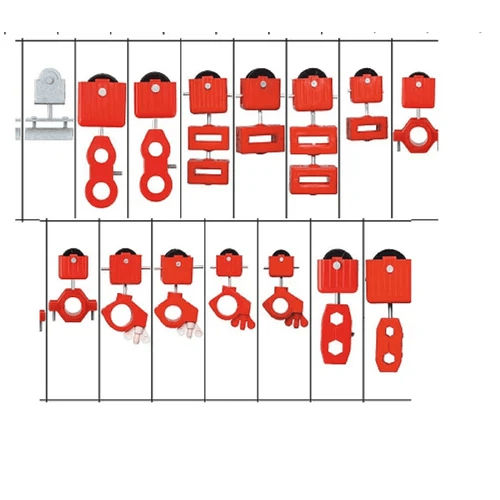

- Color RED & ORANGE

- Usage Industrial

- Product Type CABLE CARRIER

- Condition New

- Operating Mode Automatic

- Power Supply Electric

- Click to view more

X

Cable Carrier Price And Quantity

- 100 Number

- 50 INR/Number

Cable Carrier Product Specifications

- Electric

- Industrial

- CABLE CARRIER

- Automatic

- RED & ORANGE

- New

Cable Carrier Trade Information

- Yes

- Free samples available with shipping and taxes paid by the buyer

- Long wooden Case to be Packed

- Middle East Africa

- All India

- AN ISO 9001 : 2015 CERTIFIED COMPANY

Product Description

A cable carrier, also known as a cable chain, cable track, or energy chain, is a device used to manage and protect cables and hoses on machinery or equipment that move. These carriers are commonly employed in industrial automation, robotics, and other applications where repetitive movement or dynamic motion is involved.

The primary purpose of a cable carrier is to prevent cables and hoses from becoming tangled, kinked, or damaged during movement. They help to organize and guide the cables along a predefined path, ensuring reliable and efficient operation of the machinery. Cable carriers are essential in applications where cables are subjected to continuous flexing, twisting, or other dynamic stresses.

Key features of cable carriers include:

1. Flexibility: Cable carriers are designed to flex and bend with the movement of the machinery. They are typically constructed with individual links or segments that allow for flexibility while maintaining cable protection.

2. Durable Materials: Cable carriers are often made from durable materials such as plastic or metal, depending on the specific application requirements. These materials are chosen for their ability to withstand mechanical stress, abrasion, and environmental conditions.

3. Easy Installation: Cable carriers are designed to be easily installed and maintained. They usually consist of interlocking sections that can be opened to insert or remove cables.

4. Various Configurations: Cable carriers come in a variety of shapes and sizes to accommodate different cable and hose configurations. Some may be open on one or more sides, while others completely encase the cables.

5. Protection: One of the primary functions of cable carriers is to protect cables and hoses from external factors such as debris, liquids, and sharp edges that could cause damage.

6. Tension Relief: Cable carriers often include features to relieve tension on cables during movement, preventing overstretching or pulling.

Cable Carrier FAQ:

1. What is a cable carrier?

Ans: A cable carrier is a protective conduit designed to manage and guide cables, hoses, and other flexible elements in various industrial and automation applications. It typically consists of interconnected links that form a chain-like structure.

2. What are the main purposes of a cable carrier?

Ans: Below are main purposes of this product:

- Protecting cables from mechanical damage, abrasion, and environmental factors.

- Organizing and managing cables to prevent tangling and interference.

- Ensuring reliable and safe movement of cables in dynamic applications.

3. Where are cable carriers used?

Ans: Here are some of the uses of this product

- Industrial machinery and automation systems.

- Robotics and CNC machines.

- Material handling equipment.

- Automotive manufacturing.

- Packaging machinery.

- 3D printers and other motion systems.

4. How do cable carriers work?

Ans: Cable carriers typically consist of articulated links or segments that allow for flexible movement. They are installed along the path of moving equipment, and cables or hoses are placed inside the carrier. As the machinery moves, the cable carrier guides and protects the cables, preventing them from tangling or being damaged.

5. What materials are cable carriers made of?

Ans: Cable carriers can be constructed from various materials, including plastic (such as nylon or polypropylene) for lighter applications and metal (such as steel or aluminum) for heavier-duty industrial applications.

6. How do I select the right cable carrier for my application?

Ans: Factors to consider include:

- Load capacity and dynamic requirements.

- Environmental conditions (temperature, chemicals, etc.).

- Travel distance and speed.

- Cable diameter and type.

- Mounting options.

7. Are cable carriers customizable?

Ans: Many manufacturers offer customizable cable carriers to meet specific application requirements. Customization may include length, width, bend radius, and other features.

8. How do I install and maintain a cable carrier?

Ans: Installation typically involves attaching the cable carrier to the moving and stationary parts of the machinery. Regular inspection and cleaning are important for maintenance. Lubrication may be required for certain types of cable carriers.

9. What are some common problems with cable carriers?

Ans: Issues can include:

- Cable wear or damage.

- Incorrect sizing or selection.

- Insufficient lubrication.

- Contamination or debris inside the carrier.

10. Can cable carriers be used for vertical applications?

Ans: Yes, cable carriers are designed to work in vertical, horizontal, and even hanging orientations. Proper selection and installation are crucial to ensure optimal performance.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

08045801632

08045801632

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS